STROM SLS 3D Printer

High-temperature technology for advanced manufacturing

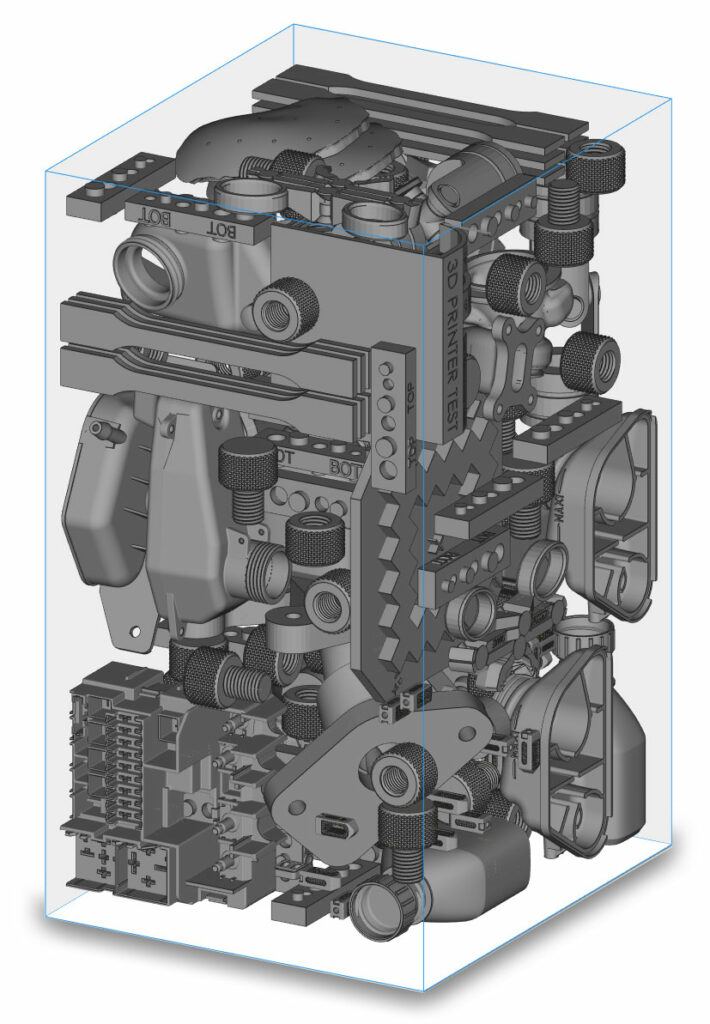

When we started developing the STROM system, we had a clear goal: to create a laser sintering 3D printer capable of reaching high temperatures – necessary to process high-performance thermoplastic materials – with industrial-grade hardware and software features.

Because a printer targeted to produce metal-replacement parts must meet the highest design standards.

And yes, there is also an R&D version of the system, designed to operate with small quantities of polymer powder, but equipped with all the features of the production version: same open software, same slicer and same temperature control system.

STROM SLS 3D printer features

-

Up to 380°C build chamber

PEKK can be processed at lower temperatures, but we always go the extra mile and the STROM is no exception to our approach. -

40W CO2 Laser, Theta-lens focusing

With fiber laser configuration available as alternative. -

Build Size: 220 x 250 x 400 mm (8.7 x 9.8 x 15.7 in)

22 Liters: a perfectly balanced volume, ideal for both end-use parts production and research laboratories. -

Build Rate: up to 2 L/h - 35 mm/h - 1.4 in/h

Allowing to print a full build in around 12 hours, including warm-up and cool-down. -

AI-enhanced scanning strategies and laser power management

While the printer flawlessy works wth "standard" slice / scan / melt strategy, we that the integration of AI-based algorithms will help to achieve the best combination of mechanical properties and printing speed. -

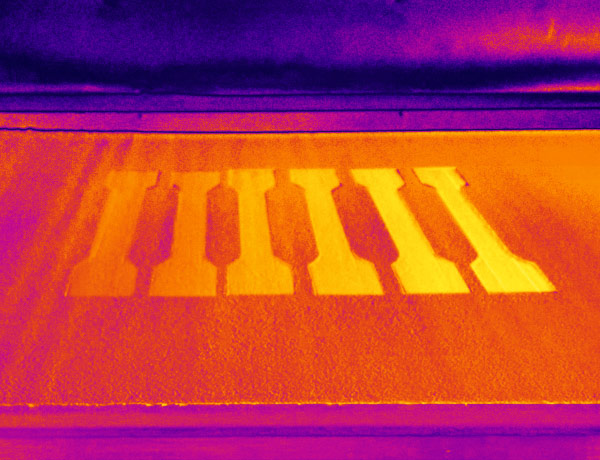

IR camera temperature control systems

Smart temperature control all over the printing bed, to ensure high process uniformity. -

Layer-by-layer image analysis Q.C.

Because advanced applications require advanced quality control tools. -

Powder management system

To allow antomatic sieving, mixing and powder tranfer system. -

Materials

The printer is designed to manufacture parts with high-performance materials, but of course will work also with standard SLS powders like PA12, PA11, PP, TPU, and PA6.

STROM scanning

STROM half-speed scanning tests (red laser coupling only for visualization purposes)

An integrated workflow

The perfect integration to the STROM PEKK 3D printer is the SM-1 automatic powder management system, which allows automated sieving and powder mixing.

But to further raise the automation bar, the two indispensable tools that complete the STROM ecosystem are the IntegAM Vibroblast Air (fully automatized depowdering system) and the IntegAM SurfPro (surface finishing).

Get in touch with us at Formnext 2024

GET IN TOUCH WITH US

Want to know more about the STROM project?