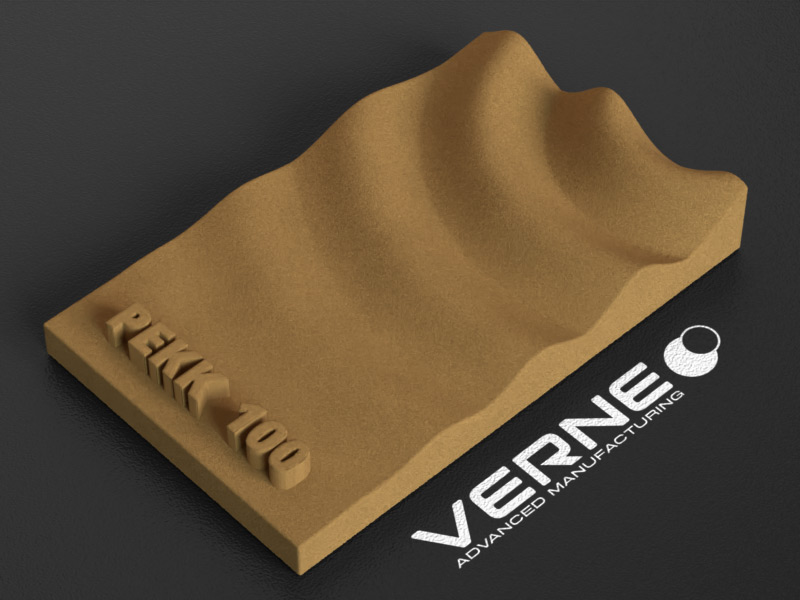

PEKK 100 (coming soon)

The ULTEM™ alternative, for laser sintering applications

PAEK polymers are semi-crystalline aromatic polyetherketones with ether and ketone groups, offering exceptional mechanical strength at high temperatures. With continuous use up to 260°C, they are flame-retardant, chemically resistant, and highly rigid, making them ideal for demanding environments, such as the aerospace and oil and gas industries.

PEKK 100 is an unfilled material for SLS that combines high impact resistance with high tensile strength.

Thanks to our high-temperature SLS technology, we can deliver our customers PEKK 100 3D-printed parts, finally matching Ultem TM-grade properties with the geometry complexity, isotropy, and surface characteristics only achievable with laser sintering.

The specs

These are some of the key specifications of PEKK 100. If you would like to find out more, please contact us here.

| PEKK 100 Properties | UoM | |

|---|---|---|

| Tensile modulus | 4 | GPa |

| Tensile strength | 74 | GPa |

| Impact strenght 23°C Unnotched | 8.75 | kJ/m² |

| Elongation at break | 1.95 | % |

| Melting point | 298 | °C |

| UL 94 V0 | Yes | - |

You can use the interactive chart on the right to compare the characteristics of the different materials available at Verne AM.

Note: The material properties shown are for general guidance only. Actual values depend on part design and processing, and may differ significantly.

GET IN TOUCH WITH US

Want to know more about high-performance & specialty materials parts 3D printing?