Medical and healthcare

PEKK (PolyEtherKetoneKetone) is a high-performance thermoplastic renowned for its exceptional mechanical strength, chemical resistance, and biocompatibility.

These characteristics make it an ideal material for demanding medical applications.

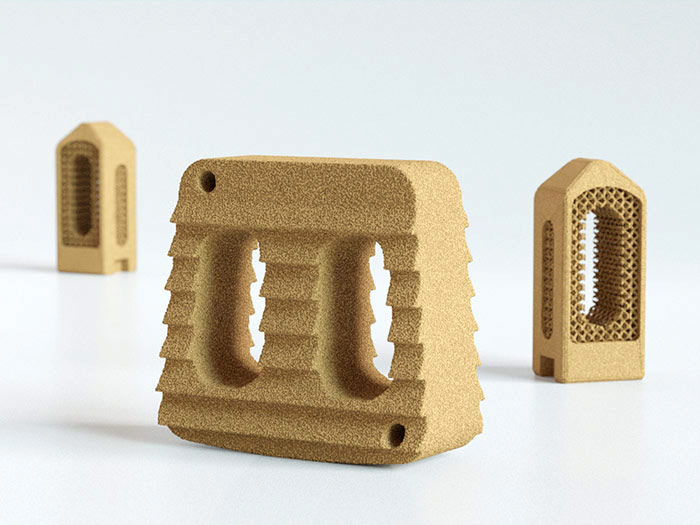

Selective Laser Sintering (SLS) 3D printing allows for the production of complex, patient-specific geometries that would be difficult or impossible to achieve with traditional manufacturing methods, and in most cases even with FDM 3D printing.

By combining the design freedom of additive manufacturing with the superior material properties of PEKK, healthcare professionals and manufacturers can achieve better patient outcomes, reduced production lead times, and highly optimized devices.

PEKK: A new era in implantology

In medical applications, SLS-printed PEKK is increasingly used as metal replacement for:

Custom implants and prosthetics: lightweight, durable, and tailored to patient anatomy.

Surgical guides and instruments: precise, sterilizable, and resistant to repeated use.

Biocompatible spinal cages / interbody fusion cages: radiolucent, with a bone-like flexural modulus, and suitable for post-processing treatments

Not just implants: 3D printing orthopedic supports

Polypropylene is another material in our portfolio with many applications for the medical field, like:

- Customized, skin-friendly, biocompatible parts

- Prosthetics, braces, supports, or orthotic devices

- Surgical guides

- Equipment that withstands repeated sterilization without deforming

- Containers for liquids, thanks to its translucency and watertightness

Our technology, your parts

From functional prototypes and custom one-off parts to low and mid-volume production runs, our SLS expertise with specialty materials makes us the perfect partner for innovation-focused companies like yours.

Share your designs and requirements with us, and we’ll respond as quickly as possible.