Aerospace and defense

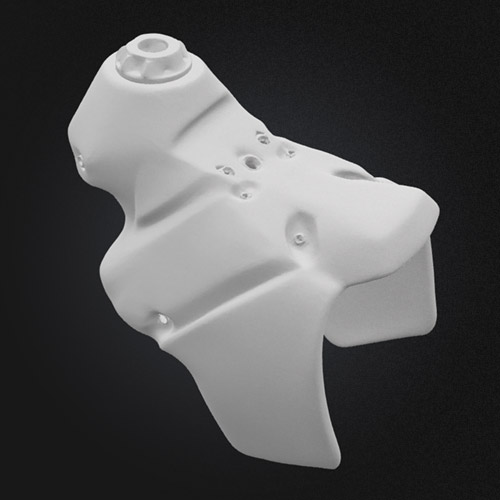

3D printing brings agility to defense and aerospace manufacturing, making complex parts once difficult (or impossible) to manufacture, feasible and affordable, while delivering short lead times.

Using high-performance polymers like PEKK, PA6, and PPS, companies can create components with unmatched strength, thermal stability, and chemical resistance, reducing the weight of drones (whether airborne, land, or sea/submarines) and satellites.

This significantly enhances their overall efficiency by reducing energy consumption, extending operational range, and lowering associated costs, three critical success factors that determine long-term performance and sustainability.

A wide range of applications

Of course, applications in this sector are not limited to unmanned vehicles and satellite systems, but can also include

Individual equipment such as helmets, and ballistic shields

Casings for electronic and optical systems that must operate in extreme environments

Containers, pipes, joints, and structural supports that are resistant to corrosion and chemical agents.

Thanks to high-performance plastic laser sintering technology, it is now possible to mass-produce a large number of parts fast, with high geometric complexities, good surface quality, and isotropic mechanical characteristics.

High performance materials portfolio

For high-end applications, standard PA11 or PA12, charged or natural grades, are not up to the task. This is where Verne AM comes to help.

PEKK

- High strength & stiffness

- Excellent chemical resistance

- Ultra-High thermal stability (Tg ~160 °C, Tm ~360 °C)

- Flame retardant

PPS

- High dimensional stability

- Excellent chemical resistance

- High thermal resistance (Tg ~90 °C, Tm ~280 °C)

- Naturally flame retardant

PA66

- High mechanical strength & stiffness

- Good wear resistance

- Chemical resistance

- High thermal resistance (Tm ~260 °C)

PA6

- Good toughness & impact resistance

- Ductile and tough

- HIgh fatigue resistance

- High thermal resistance (Tm ~220 °C)

Our technology, your parts

From functional prototypes and custom one-off parts to low and mid-volume production runs, our SLS expertise with specialty materials makes us the perfect partner for innovation-focused companies like yours.

Share your designs and requirements with us, and we’ll respond as quickly as possible.